|

|

|

|

Delta: Programmable Logic Controllers DVP10PM00M Programmable logic controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential/position control, timed counting and input/output control are widely applied to the field of industrial automation control.

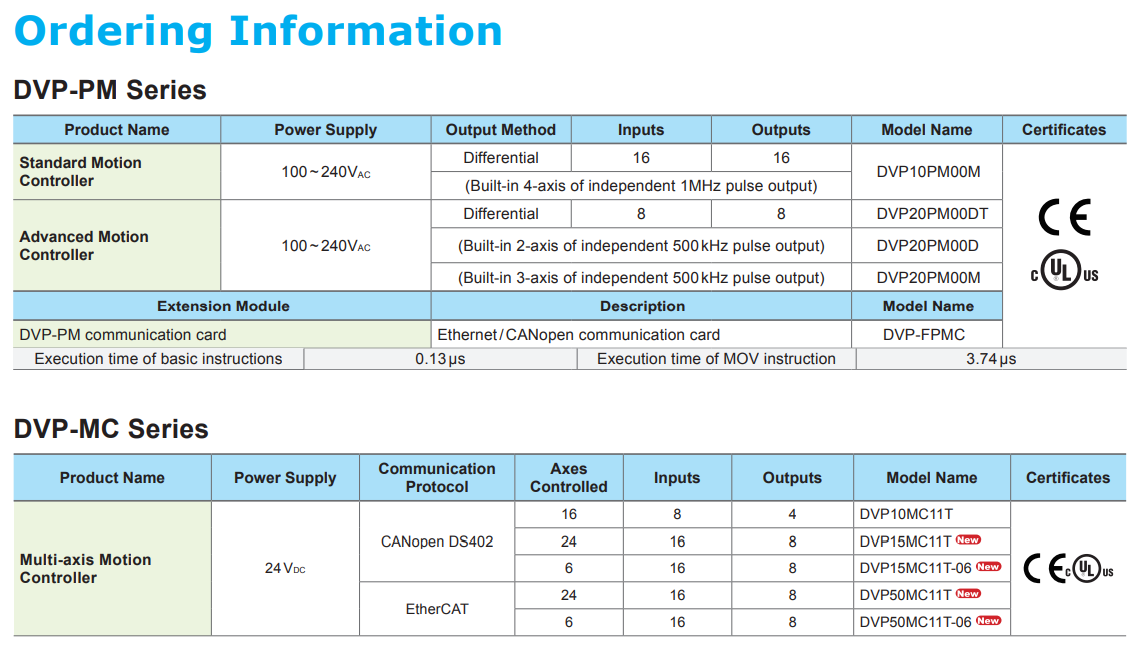

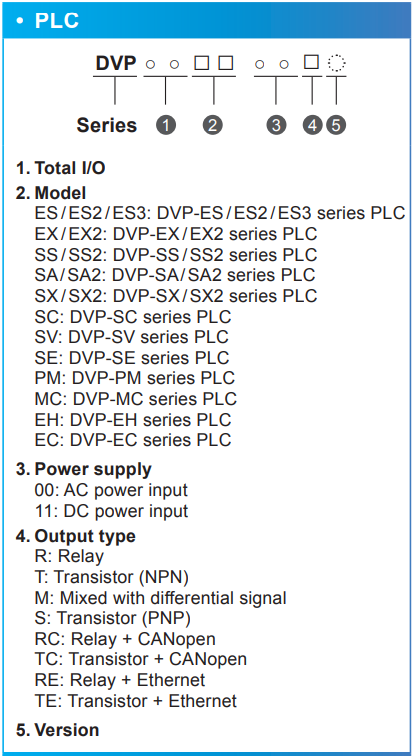

Delta's DVP series programmable logic controllers offer high-speed, stable and highly reliable applications in all kinds of industrial automation machines. In addition to fast logic operation, bountiful instructions and multiple function cards, the cost-effective DVP-PLC also supports various communication protocols, connecting Delta's AC motor drive, servo, human machine interface and temperature controller through the industrial network in to a complete "Delta Solution" for all users. DVP Series Programmable Logic Controllers Delta's DVP series programmable logic controllers offer high-speed, stable and highly reliable applications in all kinds of industrial automation machines. In addition to fast logic operation, bountiful instructions and multiple function cards, the cost-effective DVP-PLC also supports various communication protocols, connecting Delta's AC motor drive, servo, human machine interface and temperature controller through the industrial network in to a complete “Delta Solution” for all users. DVP-PM Series

The advanced PM series motion control MPU can become the motion extension module of another PM series MPU, very flexible in all kinds of applications. This series highlights high-speed command execution speed (Basic command LD for 0.1375μs, application command MOV for 2.1 μs and 1MHz differential output*4) to achieve precise motion control. MPU points: 24 Max. I/O points: 256 Program capacity: 64K Steps Built-in hardware digital filter for counting 6 high-speed counters (O.C. 200kHz*4, differential 200kHz*2), supporting U/D, U/D Dir, A/B, 4A/B counting modes 4 differential 1MHz outputs, supporting U/D, U/D Dir, A/B output modes Supports 1-speed (immediate stop after the mark arrives), 2-speed, zero return, MPG and single axis function

Highly accurate PWM 200kHz output, resolution 0.3%, Highly efficient command execution. LD: 0.1375μs, MOV: 2.1μs Electronic gear function, 8 high-speed captures (mark correction, frequency measurement), comparative output, mark/mask function (for bag making) 8 external interruptions for setting up rising- and falling-edge triggers, 1 timed interruption

Applications:

Used for 2-axis servo positioning control Material cutting machine (high-speed servo control) Crane operations Material clipper controlled by the servo

|

|

|

|

|

|

|