|

|

|

|

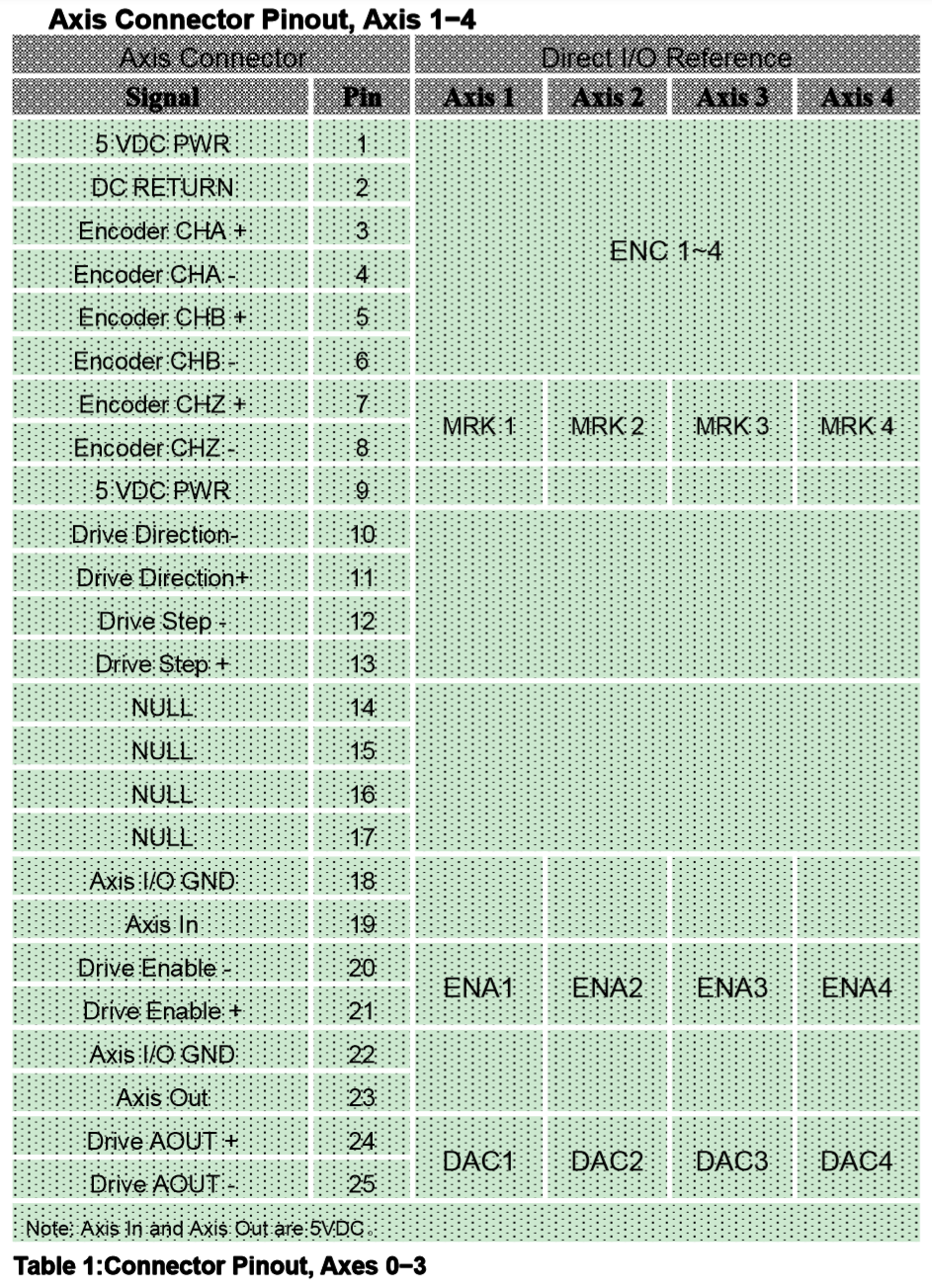

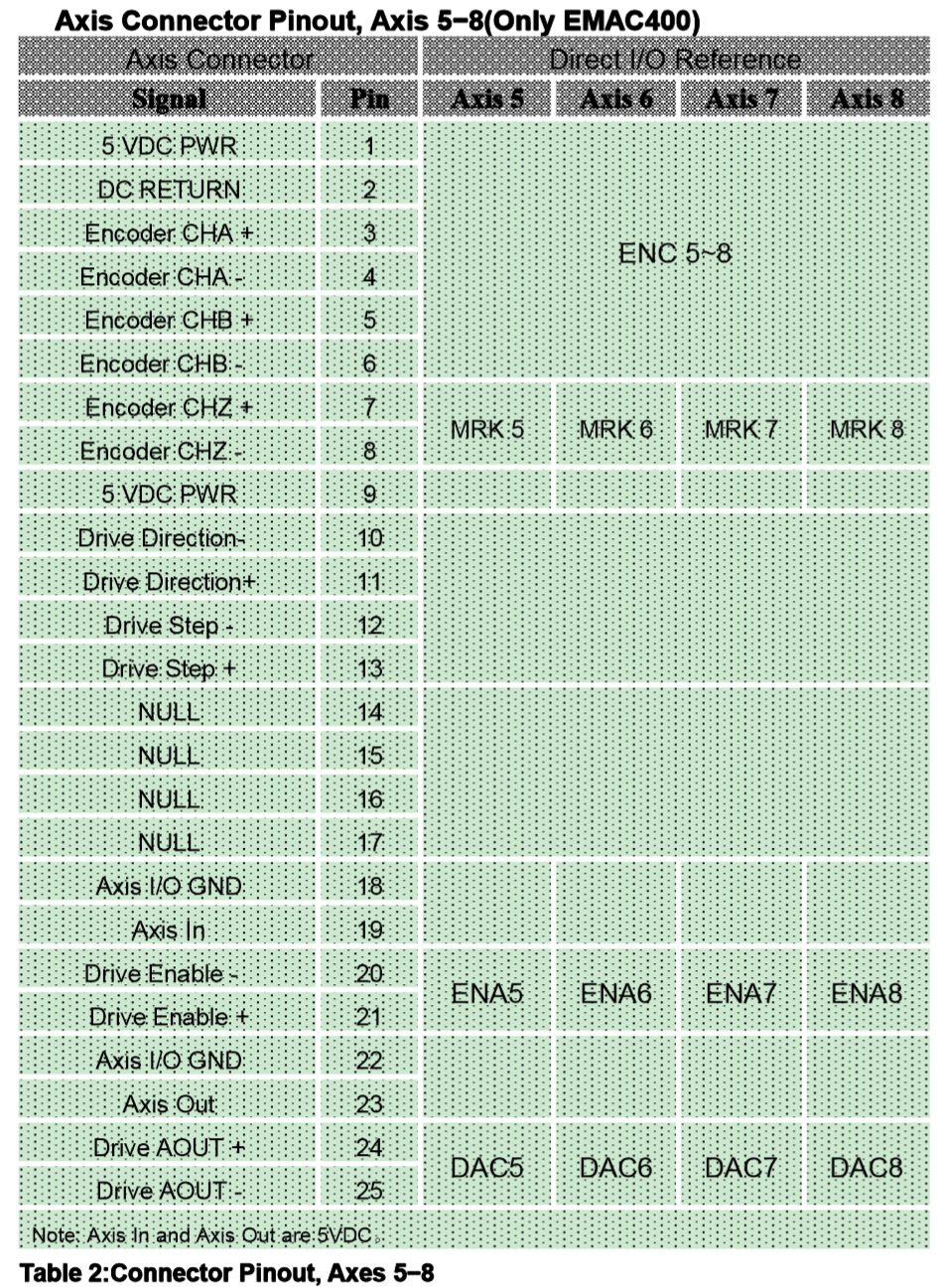

Stand-alone, user memory program. 256KB Flash/8KB RAM, DPRAM/external memory supports 64KB of dual-port ram. Ethernet, CANbus or serial communications. EMAC-200 provides 1 to 4-axis control in one unit and two Sync I/O allows the synchronization of up to 64 units (controls 256-axes) within a single system and operation within same cycle period. EMAC-400 provides 5 to 8-axis control in one unit. Supports DC brush/brushless stepper motors, such as: rotary motors, linear motors, voice coil motors, torque motors, etc. Accepts feedback incremental encoders (8 Mcounts/sec), parallel word encoders (160 Mcounts/sec), and SSI absolute encoders. Dual loop encoder inputs.

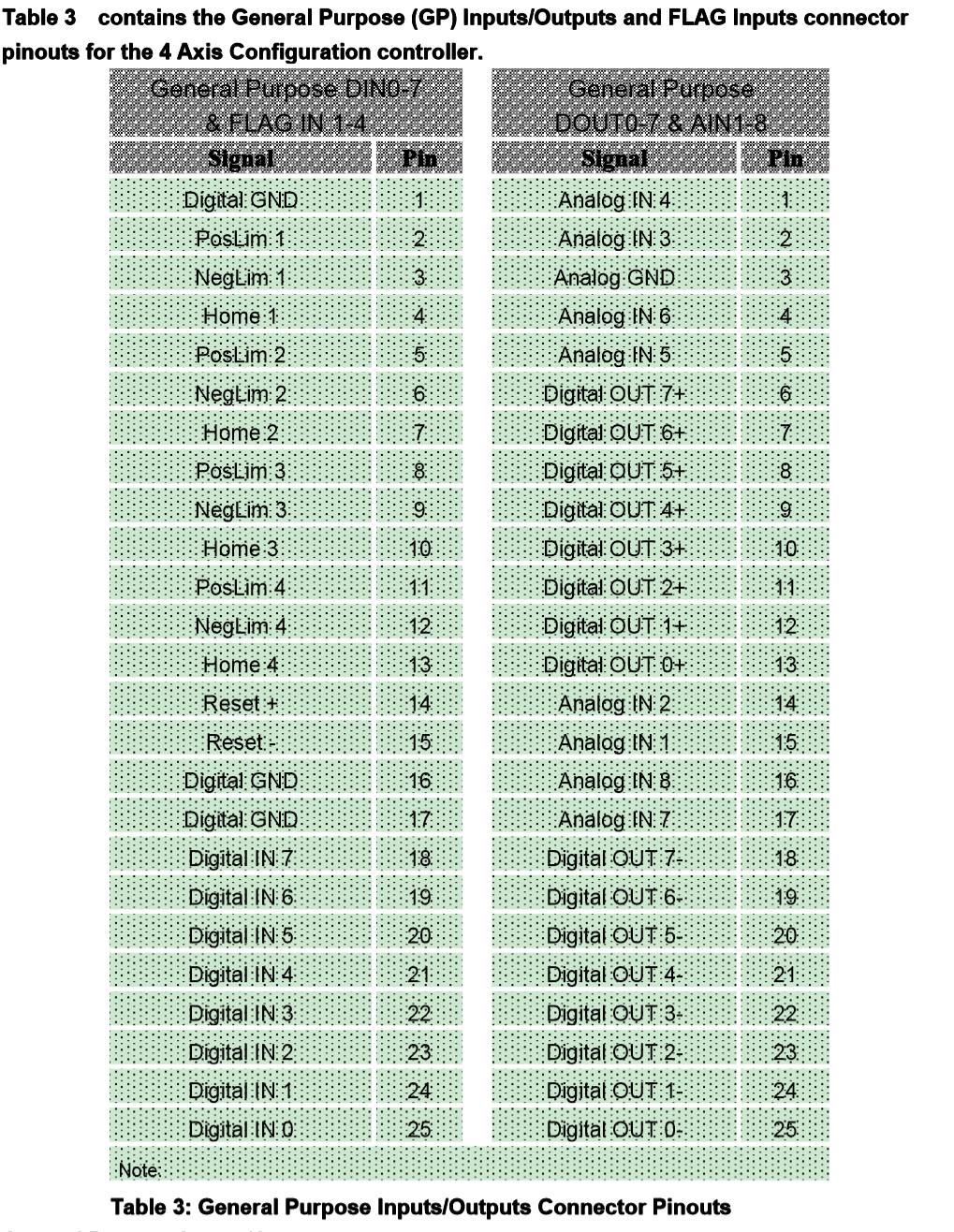

High speed loop rate: 50 μsec/axis Advanced PID filter with feedforward and dual biquad filters Profile and servo changes on-the-fly 6-step (Hall-based) and sinusoidal commutation High-speed motion trace for servo tuning diagnostics (up to 64 KB) General purpose 5-24VDC Opti digital I/O and analog inputs (EMAC-200 8 in/8 out, EMAC-400 16 in/16 out), 8 10-bit analog inputs CANbus expansion I/O Two directional limit switches, plus high speed index, and home Real-time breakpoints (2 per axis) Watchdog timer High precision 16-bit DAC or PWM output to amplifier Pulse & direction output up to 5M pulses/sec Advanced Multi-tasking Hardware & capture registers Time-based moves Software supports C/C++ or Visual Basic programming language Power supply: 90-264VDC, optional 24VDC

Standard Motion Modes Inside Firmware:

S-curve point-to-point: Position, velocity, acceleration Trapezoidal point-to-point: Position, velocity, acceleration, deceleration Electronic gearing: Encoder trajectory, position of one axis, used to drive a second axis. Master and slave axes and gear ratio parameters Electronic CAM: Encoder trajectory, position of one axis, used to drive a second axis. Master and slave axes and CAM parameters Velocity-contouring: Velocity, acceleration, deceleration; Independently programmable acceleration and deceleration values

Optional Extra Profile Motion Modes Inside Firmware and or Outside Firmware:

Interpolation of Linear, circular, sinusoidal, helical, elliptical, spline, 3D arcs Compensation of scew backless and accuracy Advanced gantry control, Synchronization of multi-axis, Tangent axis control Inverse kinematic, Traced back to the original G code program, Nubs, Look ahead, and other customization software

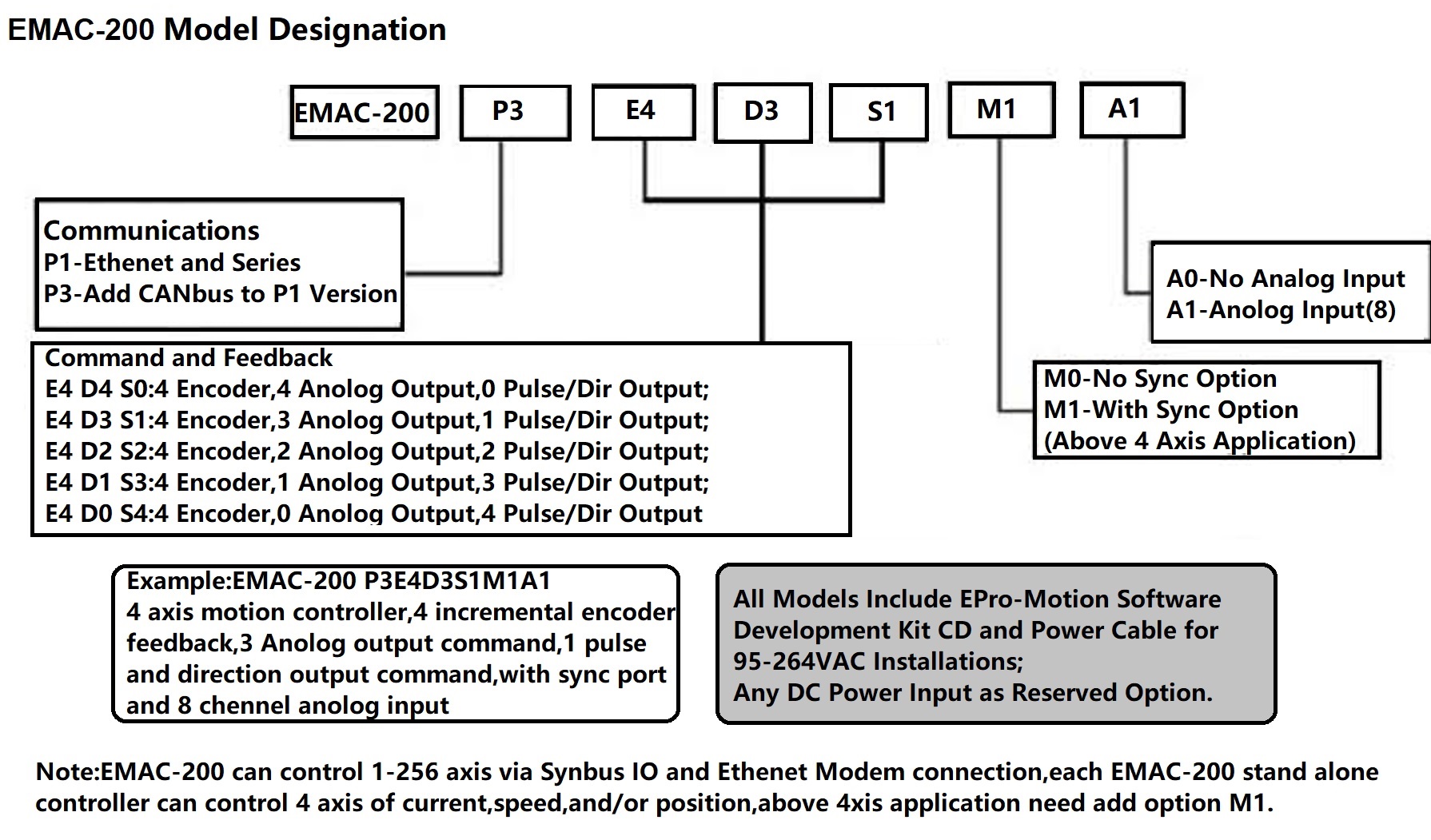

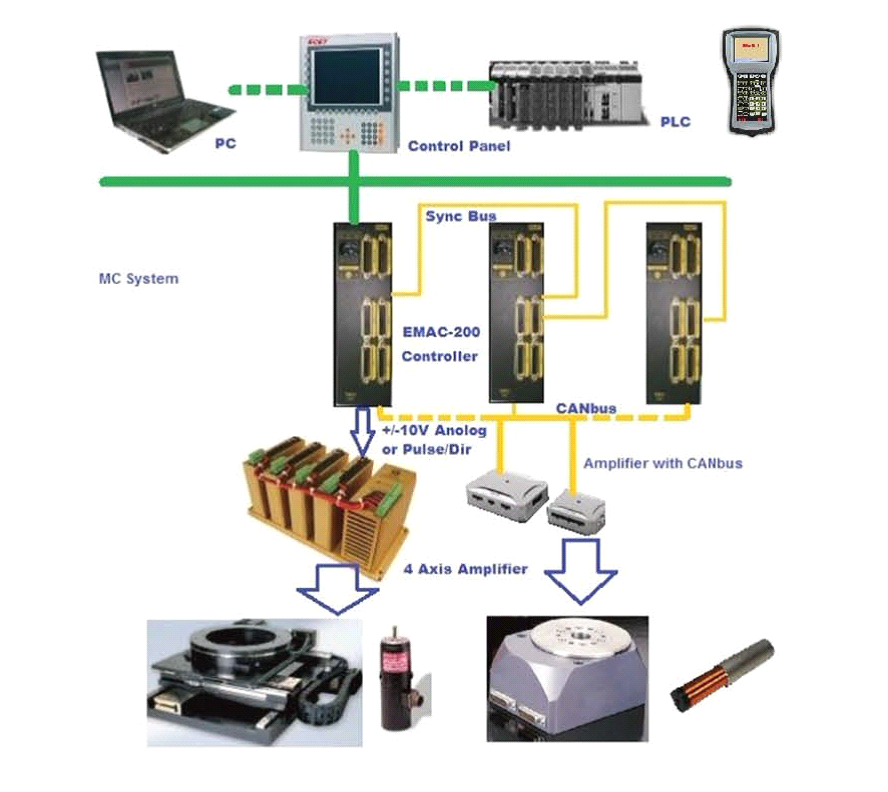

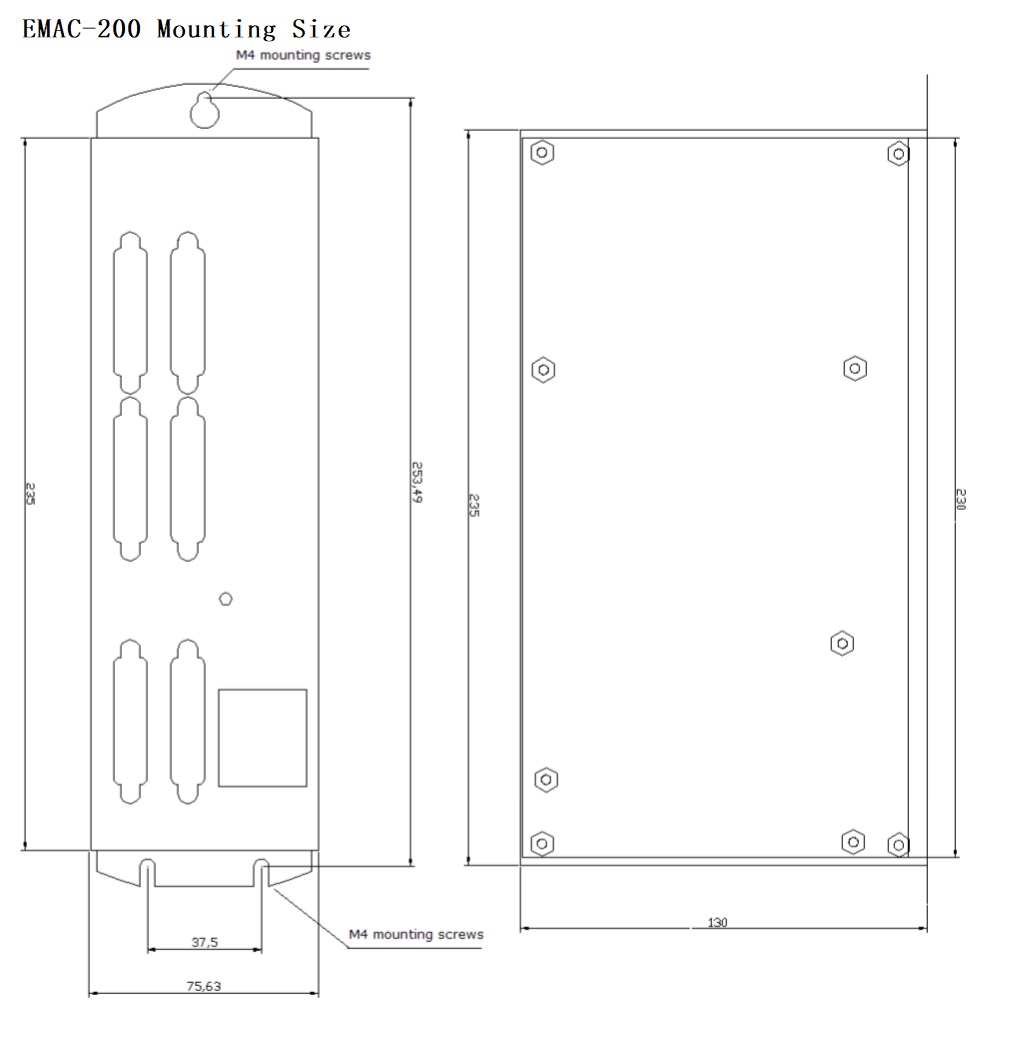

EMAC SpecificationsEMAC is designed for high speed and high precision application,servo update loop rate is 50uS/each axis,this lets system gets fast respond,high stiffness;C language program save time to be read by controller;powerful and fast calculated ability lets program running quickly.These functions let EMAC get high performance,fast executive speed,short calculate time,and keep advantage. Open technology and additional extended programming methods provide great flexibility for EMAC, and can easily establish communication with any third party peripherals, and act as the motion control module of the PLC system to make up the lack of PLC function and performance. The following picture shows EMAC connection map.  EMAC is designed in standalone metal case with an economical DB connectors, which has better anti-noise capability. Its installation connectors and dimensions are as follows:

|

|

|

|

|

|

|