|

|

|

|

Please call 833-9MOTION for the price of order over quantity of 50.

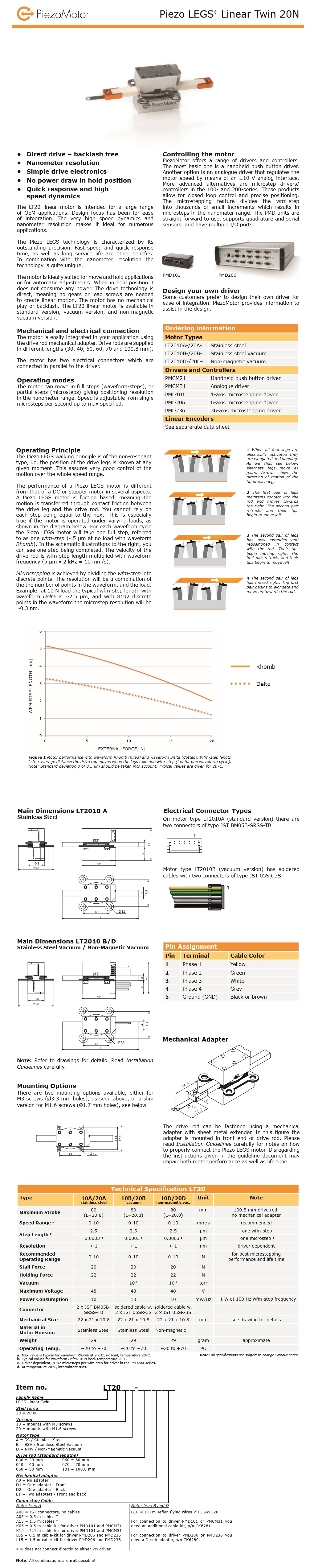

FAULHABER: Piezo LEGS® Linear Twin 20N Motors LT2010A-101D1K15 Piezo Motor Motion System 2.0.2 PiezoMotor Motion System is a free Windows software for getting started running Piezo LEGS® motors with micro-stepping driver PMD101 and/or PMD206. When installed, it gives direct access to all devices connected to your computer. The software allows open and closed-loop running, setting hardware parameters, plotting motion patterns, and programming motion sequences. The Piezo LEGS® motor uses piezoceramic “legs” to create motion. Each component consists of multiple bimorph actuators co-sintered into a single body. These movable legs, made out of ceramic “muscles”, will generate powerful linear or rotary motion and remove the need for gears or mechanical transmission. Direct drive through friction coupling ensures there is no mechanical play or backlash, and the fact that there is no slippage means motor will hold position even when powered down (not consuming any power). A unique aspect for the walking principle is the ability to divide the full step into much smaller increments. As an example, the linear Piezo LEGS® will be able to position on a sub-micron or even single nanometer level. Given that kind of resolution, it is obvious that Piezo LEGS® is the product to use for any high precision application. Reliable Positioning and Amazing Speed Range

Accurate positioning means little without reliability. As one set of legs remains engaged all the time, control of the position exists at all times. In a closed loop system, the positioning will be repeatable and precise, and the motor will be compensating the slightest error to stay on target. Piezoceramic actuators are extremely quick to respond and will do so without any peak currents. The motion dynamics of the Piezo LEGS® are truly fascinating. For a rotary motor, you have microstep resolution of less than one micro-radian and can move with constant speeds that translate to less than one revolution per week or any speed up to a maximum of ~30 rpm. Piezo LEGS® for Advanced Products and Applications Piezo technology is getting more recognition in the market for advanced products, including applications for optics, semiconductors, factory automation, defense, and medical technology. We have seen an increased demand for compact and precise motion solutions – a niche where Piezo LEGS® technology has proven to be very successful. Durability in design means you will have a reliable motion solution using Piezo LEGS®. In addition, it will enable your product in ways no traditional motor technology can. Made to Your Specification The combination of power, speed dynamics, precision, and the compact format makes Piezo LEGS® a great choice. Piezo LEGS® comes in different standard versions, including models for linear or rotary motion, vacuum compatibility, and for non-magnetic applications. However, flexibility in the design allows modifications to adapt the motor’s properties and performance to suit your application or product. This saves you time and money as you do not have to change your product to fit the motor. MICROMO works closely together with PiezoMotor – the Swedish based manufacturer of piezoelectric motors. Please contact our skilled team for questions on customizations and to discuss your application needs. Small size High force output Direct drive Backlash free Nanometer resolution Energy efficient

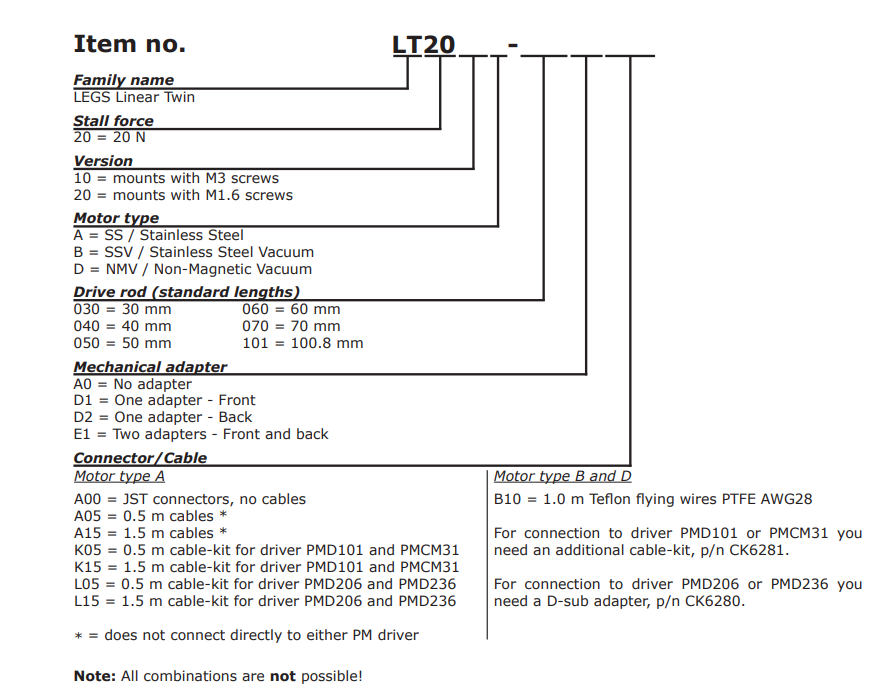

Motor: LT20 Versions: 10A, 20A, 10B, 20B, 10D, 20D Maximum Speed (mm/s): 10

Stall Force (N): 20 Step Resolution (nm): <1

|

|

|

|

|

|

|