For

applications that require the highest angular accuracy, the REXM angle encoder

offers new levels of angular metrology - better than ±1 arc second total

installed accuracy, zero coupling losses and exceptional repeatability.

Like the RESM,

the REXM stainless steel ring has graduations marked directly onto the

periphery. However, it features a thicker cross-section designed to minimise

all installation errors except eccentricity.

The remaining

eccentricity is easily corrected using the combined output of two readheads.

Renishaw's new DSi (Dual SiGNUM™ Interface) blends the output of two readheads

whilst providing a repeatable and customer programmable reference mark propoZ™

position. Once the DSi has eliminated eccentricity, the only other errors

remaining are graduation and cyclic error (sub-divisional error - SDE) both of

which are exceedingly small.

When REXM is

used with the DSi, it is possible to achieve a total installed accuracy of

better than ±1 arc second. Tests on a 183mm REXM ring have achieved an

impressive total installed accuracy of ±0.22 arc seconds.

Furthermore,

REXM maintains the dynamic performance advantages of SIGNUM™ encoders. As a

non-contact system, REXM rings are directly locked to the rotor, eliminating

coupling losses, oscillation, shaft torsion and other hysteresis errors that

plague enclosed encoders.

The total

installed accuracy of a typical REXM system is ±0.22 arc second, determined by

analysis of sequentially rotated installations.

REXM20 has a thicker cross-section, to ensure that the only

significant installation error is eccentricity. Eccentricity is easily removed

using two readheads, either with Renishaw’s DSi (Dual Signal interface), or by

combining the signals inside the host controller. The only errors remaining are

graduation errors and readhead SDE, both of which are so small they are often

negligible. As a non-contact encoder, REXM20 offers dynamic performance

advantages, eliminating coupling losses, oscillation, shaft torsion and other

hysteresis errors that plague enclosed encoders. Combining two readheads is

easy with the DSi, which also offers an angularly repeatable reference position

(propoZ ™) which is unaffected by bearing wander or power cycling.

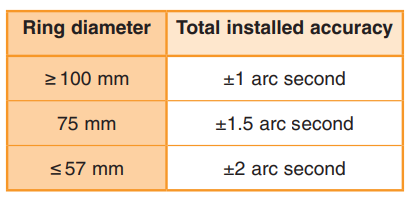

REXM20 total installed accuracy grades:

Designed for axes that are limited to partial rotation, REXT20

rings have two reference marks, oriented diametrically opposed, for use with

partial arc versions of DSi. DSi processes these reference marks to give a

single, angularly repeatable propoZ reference output.

Features

With zero coupling losses and exceptional repeatability, the

REXM/REXT ultra-high accuracy angle encoder achieves better than ±1 arc second

total installed accuracy.

•

Use with two VIONiC™, TONiC™ or SiGNUM™

encoders, combined with DSi to give ultra-high accuracy

•

Installed accuracy to ±1 arc second with dual readheads

•

Wide range of standard sizes from 52 mm

to 417 mm

•

Large internal diameter for ease of

integration

•

Flange mounted with easy 4-point

adjustment method

•

Angularly repeatable propoZ reference

position is unaffected by bearing wander or power cycling

|

REXM ultra-high accuracy rings

|

|

For ring diameters >417 mm please contact EPD

|

|

Series

|

Scale

pitch

|

Form

|

Diameter

|

Part

number

|

Price US$

|

|

REXM

|

20U (20 µm)

|

A (standard section)

|

052

|

REXM20USA052

|

2,066

|

|

057

|

REXM20USA057

|

2,066

|

|

075

|

REXM20USA075

|

2,239

|

|

100

|

REXM20USA100

|

3,702

|

|

103

|

REXM20USA103

|

3,702

|

|

104

|

REXM20USA104

|

3,702

|

|

115

|

REXM20USA115

|

3,746

|

|

150

|

REXM20USA150

|

3,789

|

|

183

|

REXM20USA183

|

3,875

|

|

200

|

REXM20USA200

|

3,961

|

|

206

|

REXM20USA206

|

3,961

|

|

209

|

REXM20USA209

|

3,961

|

|

229

|

REXM20USA229

|

4,133

|

|

255

|

REXM20USA255

|

4,362

|

|

300

|

REXM20USA300

|

5,769

|

|

350

|

REXM20USA350

|

6,888

|

|

417

|

REXM20USA417

|

8,955

|

Supporting Links

RENISHAW: REXM/REXT ultra-high accuracy angle encoder