|

|

|

|

Parker Trilogy: I-FORCE Ironless Linear Motor (ML50 Series) Parker Trilogy’s I-Force ironless linear motors offer high forces and rapid accelerations in a compact package. With forces ranging from 5.5 lbf (24.5 N) - 197.5 lbf (878.6 N) continuous up to 5.5 lbf (24.5 N) - 883 lbf (3928 N) peak, the I-Force family offers a superior combination of performance and size.

The I-Force patented I-beam shape with its overlapping windings allows for a higher power density in a smaller motor, improved heat removal, and added structural stiffness. In addition, the ironless (or air core) linear motor design has no attractive force toward the magnets. This allows for easy installation and zero cogging during motion.

Ultra high-flex cables come standard with I-Force motors. In addition, we offer modular magnet tracks for unrestricted travel length. Incredibly smooth motion, high precision and high force density make the I-Force linear motors an ideal solution for your demanding positioning requirements.

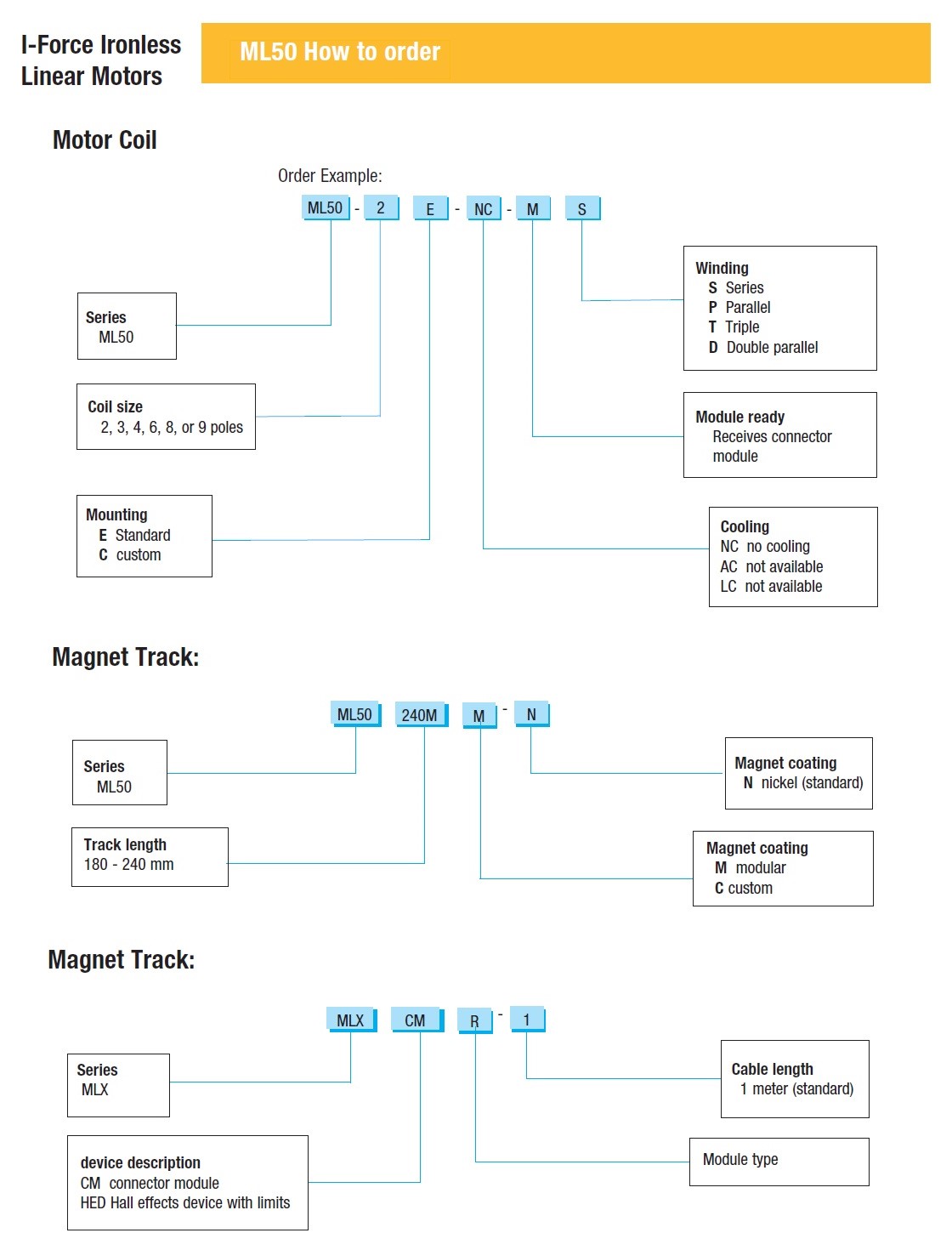

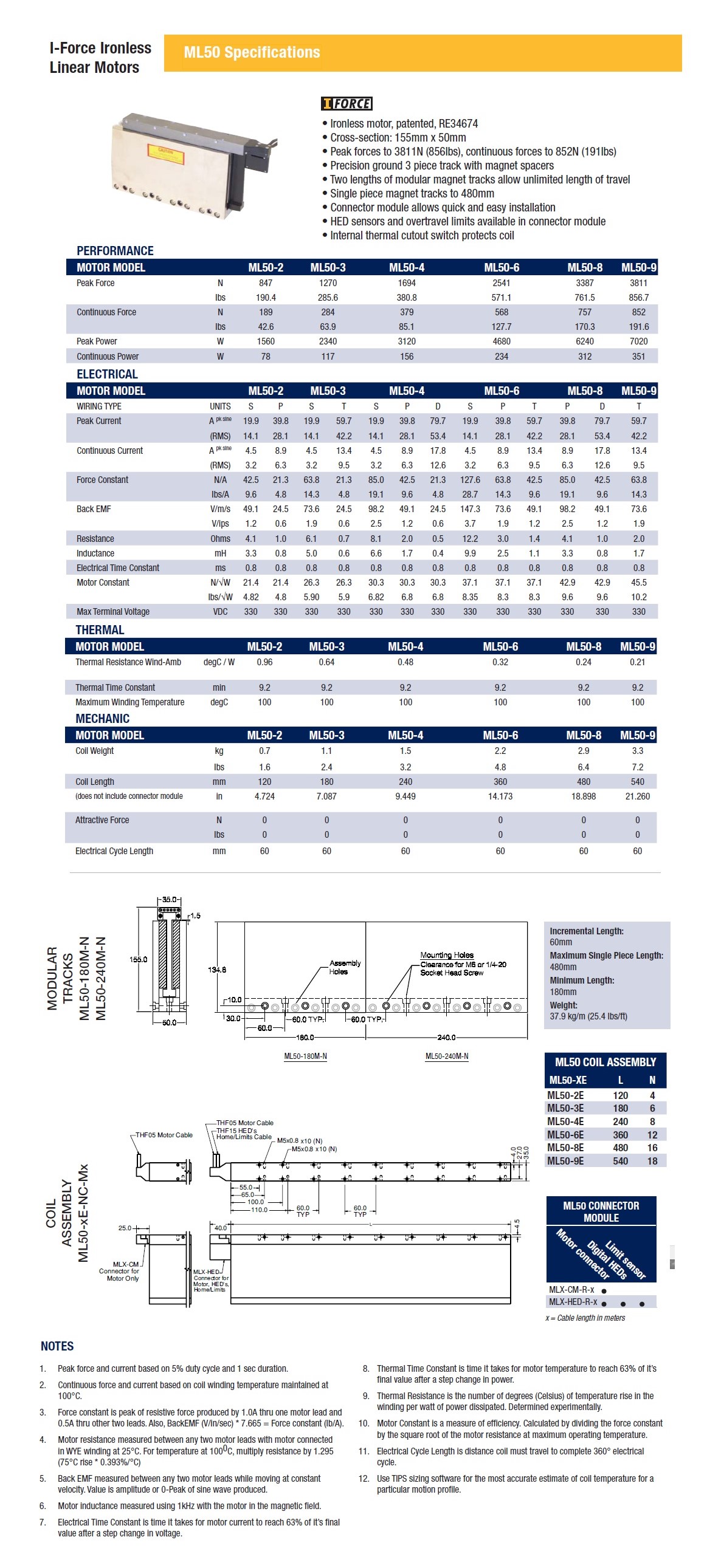

Ironless motor, patented, RE34674 Cross-section: 155mm x 50mm Peak forces to 3811N (856lbs), continuous forces to 852N (191lbs) Precision ground 3 piece track with magnet spacers Two lengths of modular magnet tracks allow unlimited length of travel Single piece magnet tracks to 480mm Connector module allows quick and easy installation HED sensors and over-travel limits available in connector module Internal thermal cutout switch protects coil

No attractive force toward the magnets:

Uses thermally conductive epoxy together with the windings (Patented RE34674):

Vacuum encapsulation process:

Embedded overtemp thermostat or optional thermistor:

High Speeds High Accelerations Fast Response – 100 times that of a mechanical system Stiffness – spring rate better than a mechanical system Zero Backlash – direct drive technology Maintenance Free Operation – mechanical simplicity due to reduced component count Long Travels Without Performance Loss Suitable for Vacuum and Extreme Environments

Semiconductor and Electronics Flat Panel and Solar Panel Manufacturing Medical and Life Sciences Machine Tools Optics and Photonics Large Format Printing, Scanning and Digital Fabrication Packaging and Material Handling Automated Assembly

Parker has one of the broadest offerings in available linear motor technologies. From component or “kit” style motors, packaged positioning tables, to complete custom engineered systems, Parker can provide a solution for any linear motion requirement.

Ironless Motors – ultra high performance and zero cogging Ironcore Motors – highest power per package size Slotless Motors – good linear force, smooth translation, low cost

Industrial Grade Positioners

Pre-engineered, ready-to-run packages Drive / amplifier connectorization High dynamic velocity and accelerations High precision

Precision Grade Positioners

Pre-engineered, ready to run packages Drive / amplifier connectorization Extremely high precision Miniature positioners available

Custom Engineered Systems

Let Parker’s extensive motion design experience, systematic project management process, and global infrastructure solve your most demanding motion problems. Collaborative development cycle aligns customer goals and rigorous performance specifications with a complete engineered solution.

Model No.: ML50-2, ML50-3, ML50-4, ML50-6, ML50-8, ML50-9

|

|

|

|

|

|

|