|

|

|

|

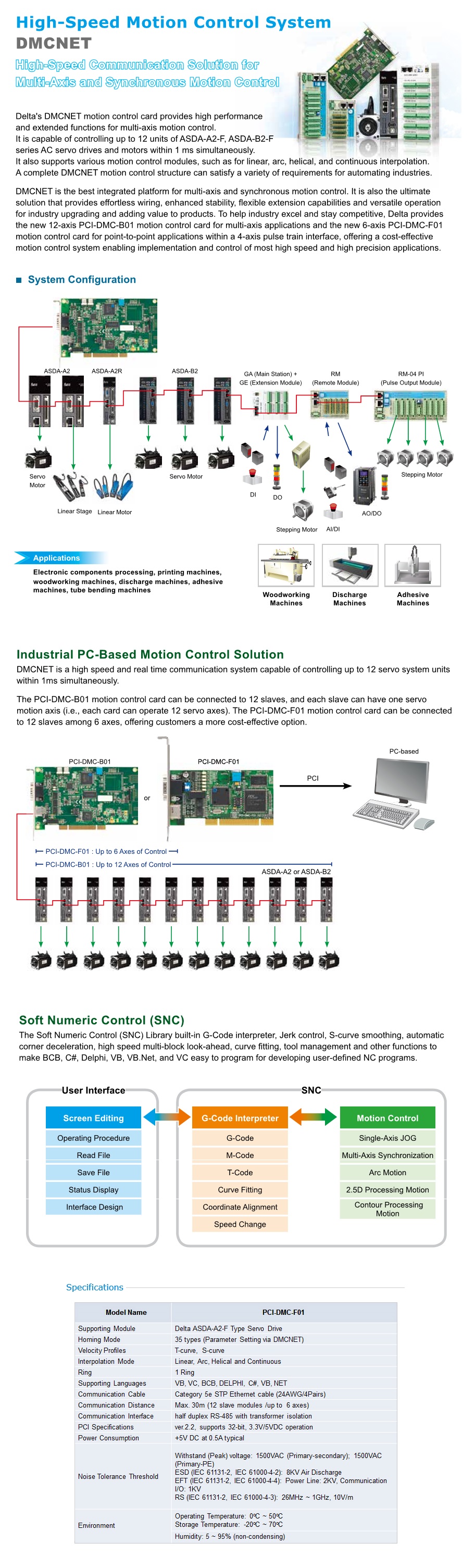

Delta: PC-Based Motion Solution - DMCNET Masters (PCI-DMC-F01 Series) DMCNET is a high speed and real time communication system, capable of controlling up to 12 servo system units within 1ms simultaneously. It can accept double precision floating point values 64-bits wide and provide up to 1,280,000 pulse/rev resolution so the servo system can make accurate calculations and provide operation flexibility. 35 homing modes are provided. 12 servo system units or 4 groups, 3-axis helical and linear interpolation or 6 groups, 2-axis linear and arc interpolation can be implemented synchronously. It also supports absolute commands, incremental commands and T-curve / S-curve velocity profiles, built-in position, speed and torque control modes for different uses. Simply by connecting to servo motors, linear motors, digital inputs and outputs (DI/DO), analog inputs and outputs (AI/AO) and other control devices such as stepping motors and manual pulse generator (MPG), enabling fast and cost-effective communication and control is easy.

DMCNET is the best integrated platform for multi-axis and synchronous motion control in a wide range of machine tools and industrial applications. It is also the ultimate solution that provides effortless wiring, enhanced stability, flexible extension ability and versatile operation for industry upgrading and adding value to the products. DMCNET stands for Delta Motion Control Network. Delta's DMCNET is a high speed and real time communication system which supports the CANopen standard CiA 402, and provides a variety of motion control functions. DMCNET is the best integrated platform capable of providing high speed, high stability and high reliability for multi-axis and synchronous motion control in a wide range of industrial applications. It is also the ultimate solution that provides effortless wiring, enhanced stability, flexible extension ability and versatile operation for industry upgrading and adding value to products. 6-Axis Motion Control Card (PCI-DMC-F01) DMCNET is a high speed and real time communication system capable of controlling up to 12 servo system units within 1ms simultaneously. It can accept double precision floating point values 64-bits wide and provide up to 1,280,000 pulse/rev resolution so the servo system can make accurate calculations and provide operation flexibility. 35 homing modes are provided. 12 servo system units or 4 groups, 3-axis helical and linear interpolation or 6 groups, 2-axis linear and arc interpolation can be implemented synchronously. It also supports absolute commands, incremental commands and T-curve / S-curve velocity profiles, built-in position, speed and torque control modes for different uses. Simply connecting to servo motors, linear motors, digital inputs and outputs (DI/DO), analog inputs and outputs (AI/AO) and other control devices such as stepping motors and manual pulse generator (MPG), enables fast and cost-effective communication and control is easy.

The PCI-DMC-F01 motion control card can be connected to 12 slaves among 6 axes. If there is an axis of motion (servo slave, pulse module slave), the node number must be in the range of 1 ~ 6. With the DMCNET structure, multiple control devices such as servo motors, remote digital and analog modules, stepping motors, direct drive motors (DD motors), and linear motors can be easily and quickly connected. Up to 20Mbps communication bandwidth is provided. Maximum distance of communication is 30m (98.4ft.) Simultaneous 3-axis linear interpolation, 2-axis arc interpolation, 3-axis helical interpolation and continuous interpolation can be implemented. Controls 6 servo axes or 2 groups, 3-axis interpolation algorithms synchronously Transfers the data of 6 servo motor units, or 768 digital inputs and outputs within 1ms simultaneously.

|

|

|

|

|

|

|