|

|

|

|

Utilizing a cost-effective Linux-based CPU, the Power Clipper will give you all the software and motion features from the Power PMAC within a low-cost, embedded solution. Extremely fast update rates (Phase and Servo) Standard PID with full feedforward model Powerful automatic tuning and analyzer tools Analog, Pulse Width Modulated (PWM), Pulse Frequency Modulated (PFM), MACRO or EtherCAT Outputs Vibration suppression filters Multiple 7th order notch and low pass filters Adaptive control for varying loads Cascaded loops (force, height, camera auto-focus control) Support for custom-written commutation routines Support for custom-written servo routines Custom routines directly in C or from MATLAB®/Simulink®

Coordinate Systems / Forward and Inverse Kinematics Up to 70 axes of coordinated or independent motion (8 local, 64 over EtherCAT) Up to 128 independent coordinate systems Up to 32 independent axes per coordinate system Dynamic axes transformations (e.g. offsets, rotations, mirroring) Forward/Inverse kinematics for non-linear mechanisms User defined routines convert between tooltip coordinates and actuator positions Permits direct specification of tooltip path

Trajectory Generation - Motion Programs Auto-coordination of multiple sets of axes Linear, circular, rapid, position-velocity-time (PVT), LIN to PVT (curve fit), Spline move modes Seamless blending between linear, circular and PVT modes Automatic move until trigger (hardware input) True S-Curve accel / decel All move modes supported with user kinematics Dynamic multi-block lookahead with velocity/acceleration control and jerk limit Sub-millisecond segmentation time Negative feed rate for true motion reversal in look ahead Move block execution rate up to 10,000 blocks/sec G-code, M-code, and T-code ready Calculations and I/O synchronous to motion Tool radius compensation, 2D or 3D

Programmable Logic Controller (PLCs) Access to all registers Trigonometric, transcendental, vector and matrix functions 64-bit floating-point architecture optimized math Executive functions for standalone operation Data gathering of up to 128 hardware/software registers per servo cycle Program in PMAC Script Program in ANSI C: Real time with preemptive kernel routines General purpose routines MATLAB®/Simulink® Embedded Coder® generated code

Position/torque compensation tables in 1D, 2D, or 3D with rollover and mirroring options 1st/3rd order interpolation between points every servo cycle Up to 256 compensation tables (64K each) Support for superimposed compensation table results Backlash compensation, fixed or in tables

Hardware Position Capture and Compare Specialized circuitry tying encoder counts to digital I/O /O on exact count (w/sub-count interpolation) at any speed (within 10 nanoseconds) For probing, registration, measurement trigger, laser firing

Follower motor(s) executes leader’s trajectory Automatic skew removal on homing Automatic gantry cross-coupling servo correction

Electronic Gearing and Cam Powerful master/slave techniques Position following (gearing) requires no program for motion External time base (cam) keeps full trajectory flexibility (non-returning, limited reversal, e.g. moving web application) Up to 256 cam tables (16k points each) Position/torque profile(s) Returning, forward/reverse travel Extremely precise synchronized outputs

Watchdog output I2T protection Encoder count error and encoder loss detection Plus/Minus over-travel, home, and user inputs Software over-travel limits Warning/fatal following error limits High speed compare outputs Automatic brake control

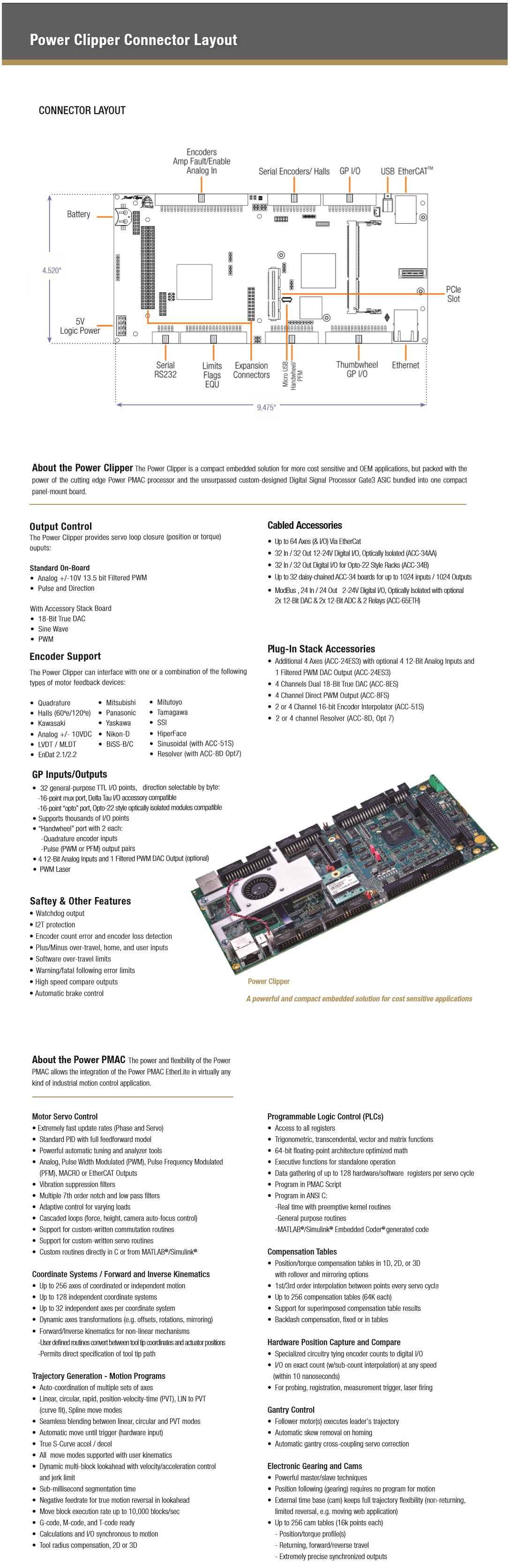

The Power Clipper provides servo loop closure (position or torque) outputs: The Power Clipper can interface with one or a combination of the following types of motor feedback devices: 32 general-purpose TTL I/O points, direction selectable by byte: 16-point mux port, Delta Tau I/O accessory compatible 16-point “opto” port, opto-22 style optically isolated modules compatible Supports thousands of I/O points “Handwheel” port with: Two Quadrature encoder inputs each Two Pulse (PWM or PFM) output pairs each 1 Filtered PWM DAC Output (optional) 4 12-Bit Analog Inputs PWM Laser Option

|

|

|

|

|

|

|