|

|

|

|

Beckhoff: TwinCAT 2 (TX1200 Series)

The Windows Control and Automation Technology

The Beckhoff TwinCAT software system turns almost any compatible PC into a real-time controller with a multi-PLC system, NC axis control, programming environment and operating station. TwinCAT replaces conventional PLC and NC/CNC controllers as well as operating devices with: open, compatible PC hardware embedded IEC 61131-3 software PLC, software NC and software CNC in Windows NT/2000/XP/Vista, Windows 7, NT/ XP Embedded, CE programming and run-time systems optionally together on one PC or separated connection to all common fieldbuses PC interfaces support data communication with user interfaces and other programs by means of open Microsoft standards (OPC, OCX, DLL, etc.)

TwinCAT consists of run-time systems that execute control programs in real-time and the development environments for programming, diagnostics and configuration. Any Windows programs, for instance visualization programs or Office programs, can access TwinCAT data via Microsoft interfaces, or can execute commands. A practically oriented software solution TwinCAT offers a precise time base in which programs are executed with the highest deterministic features, independently of other processor tasks. The real-time load on a PC is set with TwinCAT; defined operating behavior is achieved in this way. TwinCAT indicates the system load for programs that are running. A load threshold can be set in order to assure a defined computing capacity for the operating programs as well as for Windows NT/2000/XP/Vista or Windows 7. If this threshold is exceeded, a system message is generated. TwinCAT supports system diagnosis The general use of hardware and software from the open PC world requires some checking: Unsuitable components can upset the PC system. Beckhoff has integrated a practical indicator of the real-time jitter, giving administrators an easy way to evaluate the hardware and software. A system message during operation can draw attention to incorrect states. Depending on the setting, TwinCAT is started and stopped manually or automatically. Since TwinCAT is integrated into Windows NT/2000/XP/Vista and Windows 7 as a service, an operator is not needed to start the system: switching on is enough. Restarting and data backup When a program is started or restarted, TwinCAT loads programs and remanent data. To backup data and to shut down Windows NT/2000/XP/Vista and Windows 7 correctly, a UPS (uninterruptible power supply) is of great value. TwinCAT and “Blue Screen” The TwinCAT system can be configured such that real-time capability is maintained in the event of a BSOD (Blue Screen of Death) operating system crash. Real-time tasks such as PLC and NC can therefore continue to run and bring the controlled process into a safe state. Ultimately, it is the decision of the programmer whether or not to utilize this feature, bearing in mind that data or programs may already have been destroyed by the BSOD. World-wide connection through message routing – “remote” connection is inherent to the system According to the requirement for operating resources, the TwinCAT software devices can be distributed: TwinCAT PLC programs can run on the PCs or on Beckhoff Bus Terminal Controllers. A “message router” manages and distributes all the messages, both in the system and via TCP/IP connections. PC systems can be connected with each other via TCP/IP; Bus Terminal Controllers are integrated via serial interfaces and fieldbuses (EtherCAT, Lightbus, PROFIBUS DP, CANopen, RS232, RS485, Ethernet TCP/IP). Since standard TCP/IP services of NT/2000/XP/Vista/CE and Windows 7 can be used, this data can be exchanged across the world. The system offers scalable communication capacity and timeout periods for the supervision of communications. OPC provides a standardized means for accessing many different SCADA/MES/ERP packets.

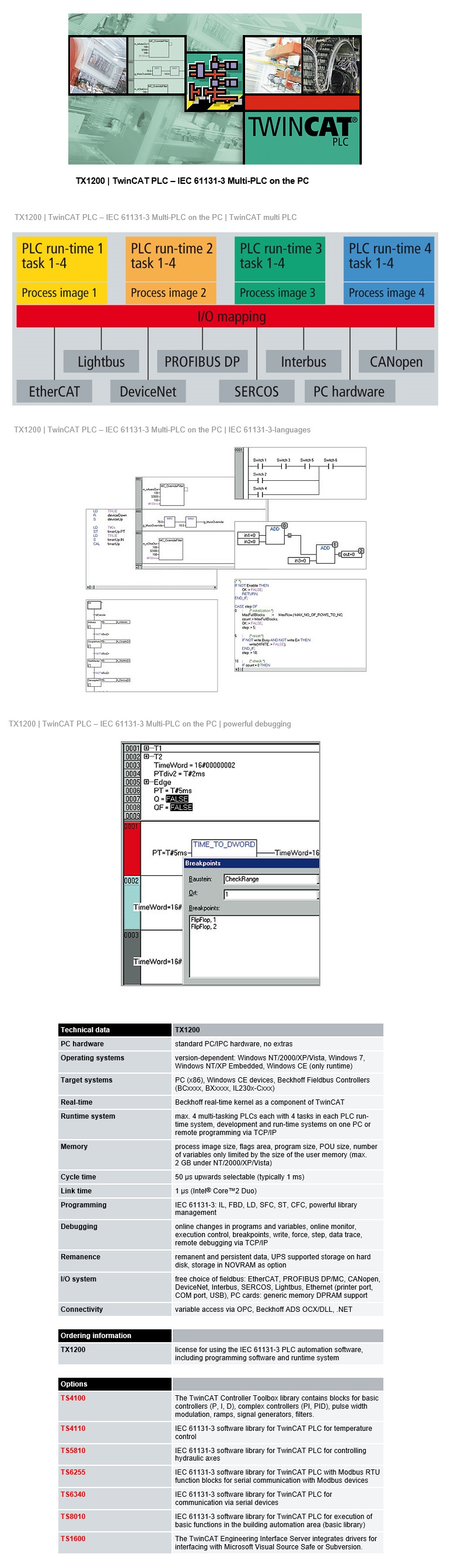

TX1200 | TwinCAT PLC – IEC 61131-3 Multi-PLC on the PC

Software PLC for Windows NT/2000/XP/Vista or Windows 7 The TwinCAT PLC is programmed in accordance with IEC 61131-3 independently of the manufacturer. Online connections with PLC runtime systems around the world can be implemented with TCP/IP or via fieldbuses on the IPC. TwinCAT PLC programming system TwinCAT PLC offers all the languages in the IEC 61131-3 standard and has a powerful development environment for programs whose code size and data regions far exceed the capacities of conventional PLC systems. Online connection via networks Changes to programs or data are supported by a very powerful link to the runtime systems, which can also operate over a network. All the usual facilities of a PLC are available. Any Windows programs, for instance visualization programs or Office programs, can access TwinCAT data via Microsoft interfaces or control the PLC. Practically oriented properties all defined programming languages: IL, FBD, LD, SFC, ST and CFC certified in accordance with base level (IL/ST) structured programming with modular program management recompilation while PLC runs with maximum data retention (online change) convenient library management source code storage in target system criterion analysis conversion between languages incremental compilation all common data types, structures, arrays, including multi-dimensional arrays programming support: auto-format, auto-declare, cross reference, search/replace project compare program converting in different languages connection with source code management tools

Diagnosis using standard PC techniques Changes of any size to program and data can be carried out “online”. Error location and correction (debugging) is supported by aid of a very powerful link to the runtime system. This can also be used over a network. All the usual features of a PLC are available. Online connections with PLC runtime systems around the world can be implemented with TCP/IP or via fieldbuses. online change of new variables, instances or programs at runtime with maximum data retention online monitoring of variables in variable lists, watch windows, editors online status and powerflow (accumulator contents) of programs and instances triggering, forcing and setting variables single step, breakpoints step into, step over display of the current call stack Watch list shows a selection of variables. Trace function records variable values for every cycle. online management of all variable names and structures across the whole system TwinCAT ScopeView as a graphical diagnostic and analysis tool for the display of values

|

|

|

|

|

|

|